We use cookies on this site to improve our service, perform analytics, and remember website preferences. By using this site, you consent to these cookies. For more information visit our Privacy Policy

Integrating FDA reprocessing guidance into Human Factors validation tests

HHF developed a novel hybrid approach to test workflows for medical device reprocessing that accommodates two seemingly contradictory FDA guidances. This new approach was found to be useful for validating the comprehension of reprocessing instructions while evaluating the overall use-safety of the device in a single human factors study.

Project Type

Validation test development for device reprocessing

Services

Regulatory compliance support, summative testing

Challenge

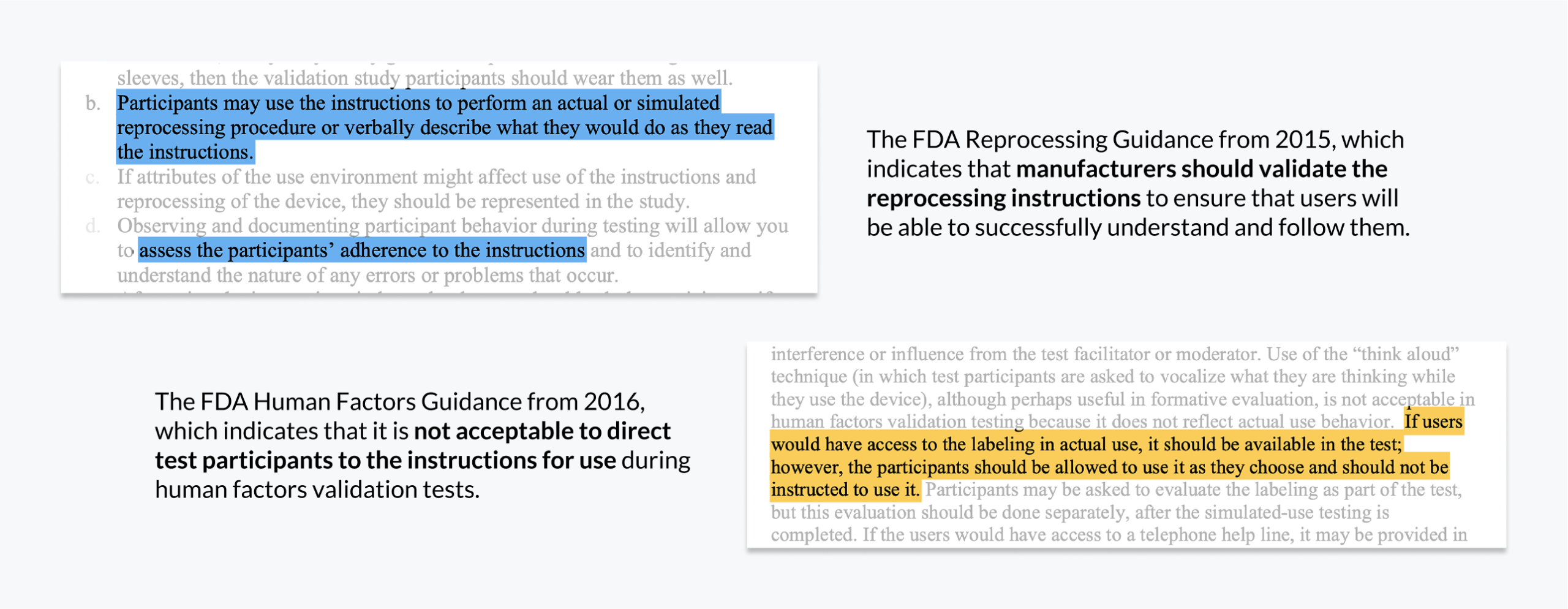

Medical device reprocessing (cleaning and sterilizing tools for reuse) is critical to preventing infections. In the U.S. Food and Drug Administration (FDA) guidance from 2015, ‘Reprocessing Medical Devices in Health Care Settings: Validation Methods and Labeling,’ they identified a subset of medical devices that pose a greater likelihood of spreading contamination if not adequately reprocessed, such as bronchoscopes, endoscopes, colonoscopes, arthroscopes, and laparoscopic instruments. This reprocessing guidance indicates that manufacturers should validate the reprocessing instructions to ensure that users will be able to successfully understand and follow them. However, based on the FDA Human Factors Guidance (2016) it is not acceptable to direct test participants to the instructions for use (IFU) during human factors (HF) validation tests. This contradicts the approach for HF validation testing for medical device reprocessing. This discrepancy in regulatory guidance posed a significant challenge for manufacturers seeking FDA compliance.

To resolve this, we sought to develop a testing approach that would adequately assess the reprocessing instructions while following the FDA’s different guidelines as closely as possible. Our hybrid testing methodology succeeded in accommodating multiple regulatory requirements while ensuring that the device manufacturers were given valuable information about the safety of their device’s reprocessing workflow.

Process

HHF discussed two different approaches with the FDA:

- Option 1: All participants conduct tasks once in accordance with the reprocessing guidance. The test moderator would point to the relevant section in the IFU and would explicitly direct participants to read and follow the instructions.

- Option 2: All participants conduct tasks twice, with each approach satisfying one of the guidances. First they would follow the HF guidance approach: the test participants would be given access to the IFU but would not be explicitly told to use it while conducting tasks. Then, they would follow the reprocessing guidance approach: the test moderator would then point to the relevant section in the IFU and would explicitly direct participants to repeat the tasks, this time while reading and following the instructions.

In response to these approaches, the FDA indicated that “explicitly having the participants refer to the IFU and validating that participants are able to understand and follow the instructions” was the requirement. However, the FDA also indicated that they would prefer if the participants initially performed simulated use testing without direction, followed by explicit reference to the IFU afterwards.

Pilot Testing

We conducted a pilot study for a device manufacturer that tested both options. From pilot testing, it was determined that Option 2 (conducting tasks according to both guidances) was overly time consuming. The testing sessions took over four hours for the participants to complete all the reprocessing tasks just once. On the other hand, the manufacturer felt that Option 1 did not validate the reprocessing materials and workflow sufficiently. As a result, HHF proceeded with an integrated approach that combined these two options together.

Iterative Testing

The final testing workflow consisted of the test moderator instructing the participant to read the relevant section of the instructions for use and then proceed to reprocess the device. To assess participants’ ability to navigate the IFU, the moderator would not direct the participant to the page or section in question. In instances where the participants did not read the IFU and incorrectly reprocessed the instruments from memory, the moderator would then have the participants repeat the scenario a second time after reading the relevant sections in the IFU.

HHF had the opportunity to refine the approach based on iterative pilot testing. Some notable insights were gathered during this process. Including the following:

Findings

Reprocessing technicians do not typically read instructions while they clean instruments; they rely on memory or aides within the environment (such as videos, posters, or peers). Thus, this testing approach was not necessarily representative of their typical reprocessing procedures.

Instructions for use often target different user groups: clinicians and reprocessing technicians. Integrating instructions for multiple user groups in the same IFU can result in confusion.

Training mitigations can greatly affect success in reprocessing adherence. For example, outcomes may be improved by providing greater familiarity with the names of instrument parts and providing greater reasoning for instructions that may differ from reprocessing procedures of instruments currently used in hospitals.

Simulation artifact should be considered when determining test design. Using visibly clean instruments during testing when multiple acceptance criteria are used in practice (such as both brushing the instrument a specific number of times, or until the instrument is visibly clean) can result in users brushing the device fewer times than they would in practice.

Outcomes

This new approach was assessed through multiple pilot studies and was found to be useful for both validating the adherence to and comprehension of reprocessing instructions while still being able to help evaluate the overall use-safety of the device in a single human factors study. The integrated approach allows for an understanding of users’ interactions with the device in a use environment that is as realistic as possible while being able to explicitly assess the reprocessing instructions and other reprocessing materials. It also accounts for workflow differences, in which additional safety checks may be taken that go above and beyond the manufacturer’s recommendations. As a result, this approach provided the manufacturer with additional insight into reprocessing practices which may not have been previously considered and allowed them to adjust their documentation accordingly.

Pilot and formative studies that involve reprocessing instructions are especially helpful to identify instances of confusion and allow for the manufacturer to make quick iterations to improve IFU clarity, such as changing the wording of specific instructions, modifying training guidelines, or reordering sections within the IFU. HHF’s approach allowed the reprocessing instructions to be validated in a manner that aligned with the FDA guidances while also gathering additional insights for creating improved reprocessing instructions in the future.

About HHF’s Evaluation & Regulatory Services

Our team works with healthcare organizations, including the top 10 medical device companies in the world, to ensure products are safe and effective for intended users, uses and use environments. We have extensive experience with FDA, European, and international usability requirements and can tailor our services specifically to your needs.

To better understand the medical device reprocessing process, we shadowed technicians at University Health Network.